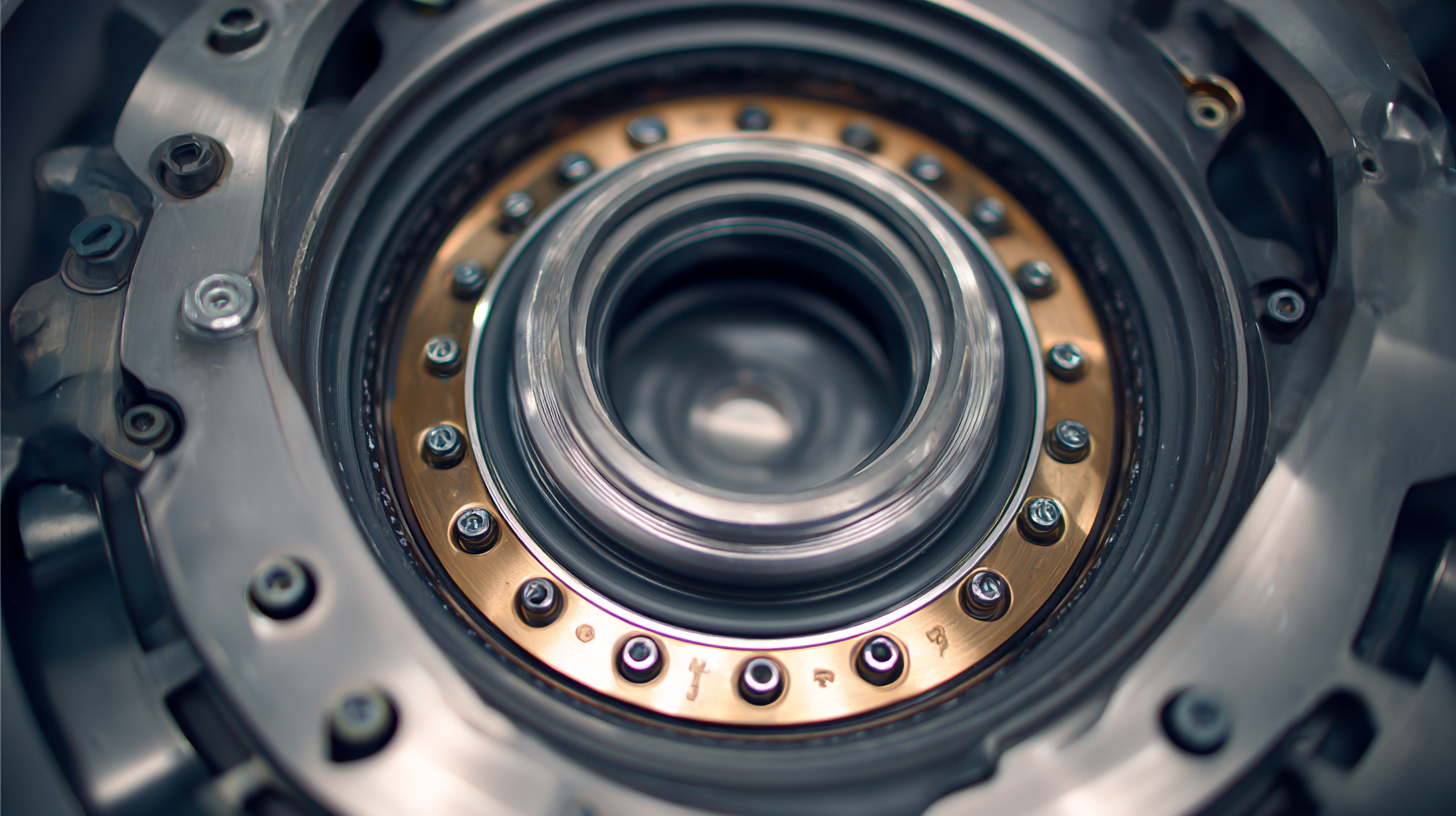

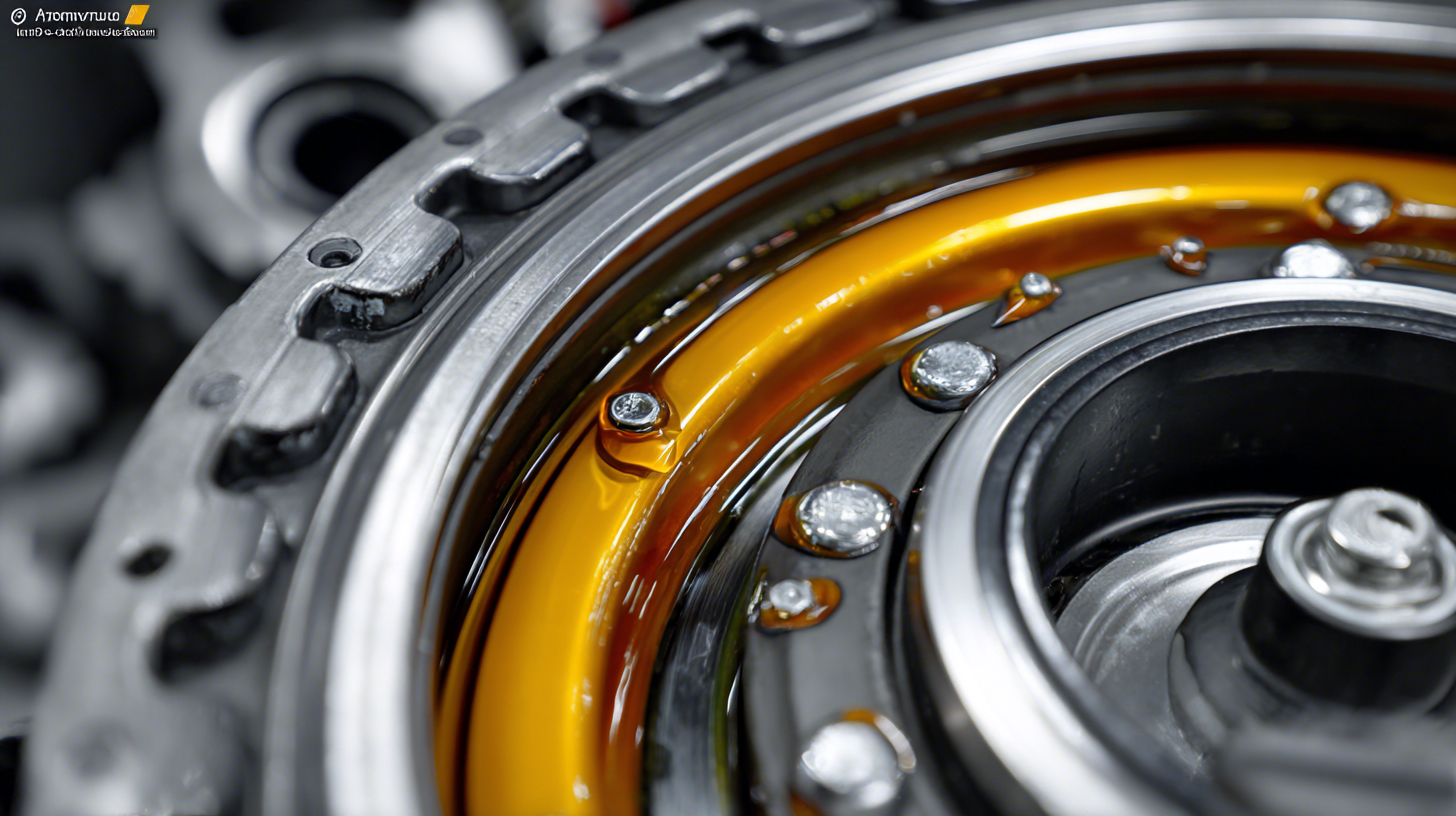

In the automotive industry, the importance of high-quality components cannot be overstated, and one such critical component is the automobile oil seal. According to a report by Grand View Research, the global automotive sealing systems market is expected to reach USD 56.83 billion by 2025, driven primarily by the increasing demand for advanced sealing solutions in vehicles. Oil seals play a vital role in preventing oil leaks, protecting engine components from dirt and contaminants, and maintaining overall system efficiency.

As automotive technology advances, the specifications for these seals have become increasingly intricate, necessitating an informed selection and proper installation process. This comprehensive guide aims to demystify the technical specifications of the best automobile oil seals, providing essential tips and insights to help you make informed decisions that enhance the performance and longevity of your vehicle.

When selecting an automobile oil seal, several technical specifications come into play, including material type, sealing technology, and compatibility with various environments. According to recent industry reports, factors such as temperature resistance and chemical compatibility can significantly affect the performance of oil seals in different applications. For instance, the choice between elastomeric seals and thermoplastic seals often hinges on the automotive application, where exposure to extreme temperatures and contaminants is a concern.

Market analysis indicates that the automotive oil seal industry is of considerable importance, particularly in the context of rising vehicle production, projected to reach approximately 100 million units globally by 2025. Additionally, the trend towards electric vehicles has also influenced oil seal selection, as these vehicles require seals that can withstand different operating conditions compared to traditional internal combustion engines. This shift necessitates a thorough understanding of the types of seals that are suitable for electric vehicle components, contributing to innovative solutions in the automotive sealing market.

As manufacturers increasingly focus on enhancing sealing solutions for modern vehicles, it’s essential to consider the specific material properties and seal geometry that best suit the application, ensuring reliability and performance in the long-term operation of both conventional and electric vehicles.

When it comes to selecting oil seals for automotive applications, understanding the different types available and their specific functionalities is crucial. Oil seals come in various configurations, including rotary lip seals, which are widely used in engines and drivetrain components due to their ability to withstand extreme temperatures and pressures. For example, the global market for metal seals, which also includes oil seal applications, was valued at approximately $1.9 billion in 2024 and is projected to reach $3.1 billion by 2034, growing at a CAGR of 4.7% from 2025. This highlights the increasing demand for reliable sealing solutions across various industries.

Furthermore, the flexible graphite market, relevant for high-performance sealing applications, is estimated to grow from USD 0.35 billion in 2025 to USD 0.45 billion by 2030, reflecting a CAGR of 5.5%. This growth indicates a shift toward advanced materials in the automotive sector that can provide enhanced durability and resistance to harsh environmental conditions. Understanding these trends and specifications is essential for selecting the right seal for your automobile, ensuring optimal performance and longevity.

| Type of Oil Seal | Material | Temperature Range (°C) | Pressure Rating (bar) | Application |

|---|---|---|---|---|

| Rotary Oil Seal | Nitrile Rubber | -40 to 120 | 20 | Engine, Transmission |

| Lip Seal | Fluorocarbon | -20 to 200 | 15 | High-performance applications |

| TC Seal | Polyacrylate | -30 to 150 | 25 | Automotive axle, Gearboxes |

| O-Ring Seal | EPDM | -50 to 120 | 10 | Cooling systems, HVAC |

| Spring Energized Seal | PTFE | -200 to 260 | 30 | Extreme temperature applications |

When it comes to installing oil seals for optimal performance, understanding the correct techniques is crucial. First, always ensure that the sealing surface is clean and free from any debris or corrosion. A clean surface is essential for creating a tight seal that prevents leaks. Before installation, inspect the oil seal for any visible damage or wear; using a damaged seal can lead to premature failure.

Another important tip is to use the right tools for installation. A drifter or seal installer can help apply even pressure when seating the seal, preventing it from becoming distorted. Additionally, ensure that any surrounding components are properly aligned to avoid putting unnecessary stress on the seal during installation. Take your time during this process; rushing can lead to mistakes that might compromise the seal's effectiveness.

Lastly, always lubricate the lip of the oil seal lightly before installation. This can assist in easier seating and reduce the risk of tearing during the installation process. Proper lubrication can also enhance the seal’s performance by allowing it to operate smoothly against the shaft, ensuring a longer lifespan and better efficiency.

When selecting oil seals for vehicles, it is crucial to avoid common mistakes that can lead to performance issues and even damage to the engine. One prevalent error is opting for substandard or incompatible oil seals. As highlighted by industry experts, the quality of automobile components can vary significantly, and using inferior products often results in leaks and engine malfunctions. Always verify that the seals match the vehicle's specifications to ensure compatibility.

Another frequent mistake is neglecting to consider the application and environmental conditions where the vehicle operates. Different driving conditions, temperatures, and fluid types can impact the performance and durability of oil seals. For instance, seals designed for high-performance engines may differ in material and design compared to those for standard vehicles. Proper selection based on these factors reduces the risk of premature failure and enhances the longevity of the engine.

Finally, an often-overlooked aspect is the installation process. Even the best oil seal can fail if not installed correctly. It is vital to follow manufacturer guidelines carefully and to use the right tools during installation to prevent damage. Ensuring that the sealing surfaces are clean and free from debris will also contribute to optimal functionality. Avoiding these mistakes will help vehicle owners maintain their engines effectively and prolong their lifespan.

The quality of oil seals plays a critical role in enhancing vehicle efficiency and longevity. As per industry reports, the global gaskets and seals market was valued at approximately USD 4.7 billion in 2023, with an anticipated growth to USD 9.2 billion by 2035. This significant expansion underscores the increasing recognition of high-quality components in automotive design. With advancements in materials like rubber and metal, modern oil seals are engineered to withstand higher pressures and temperatures, ultimately contributing to improved engine performance and fuel efficiency.

Furthermore, the mechanical seals market is also expected to experience consistent growth between 2025 and 2035, driven by the rising demand for high-performance components across sectors, including automotive and aerospace. Quality oil seals are instrumental in maintaining proper lubrication and preventing leaks, which are essential for minimizing wear and extending engine lifespan. As vehicles become more sophisticated, investing in top-notch oil seals can significantly improve overall vehicle reliability and performance, making them an integral focus for manufacturers and consumers alike.

TradeManager

Teams

VKontakte